This looked suspicious:-

. . . and from the inside by the back seat you can see why:-

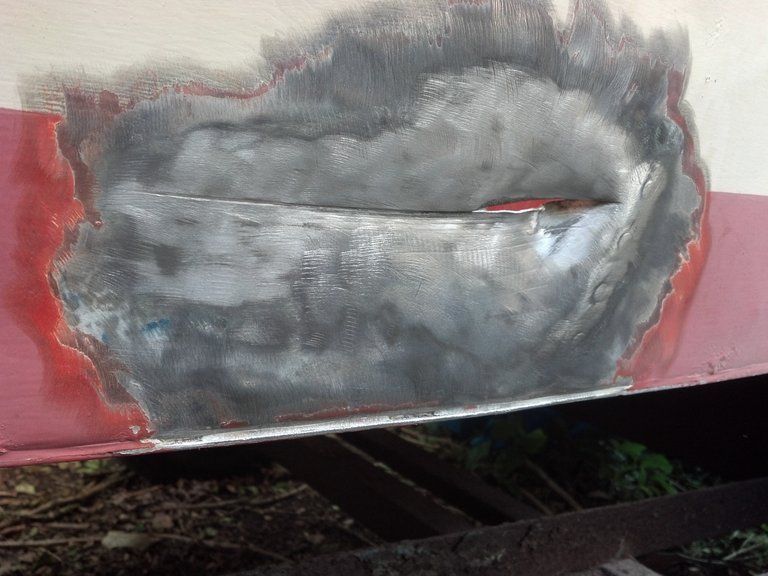

Even worse without the paint - revealing a slit and the back of some filler:-

One good thump later out came this:-

. . . leaving this!:-

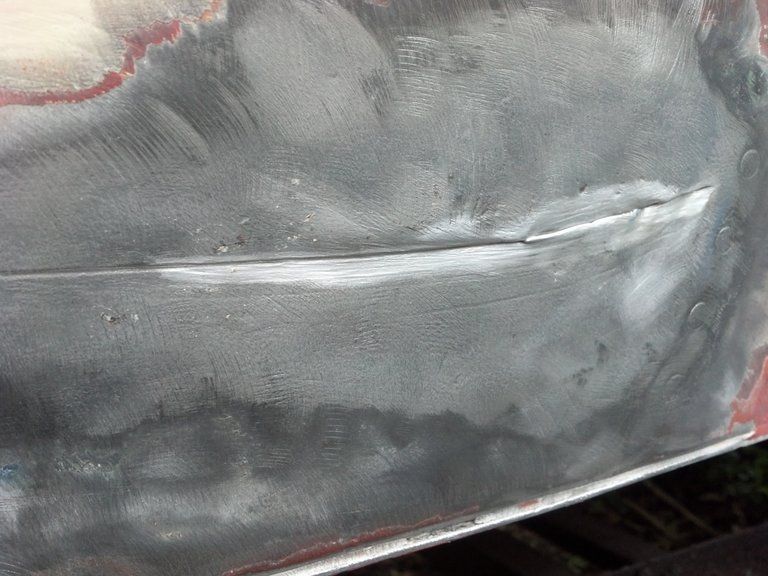

Out with the panel hammers and dollies:-

. . . . but still a stretched panel:-

Hmmmm

I don't think that's too bad for a first time effort!